| Enlarge Image |

|

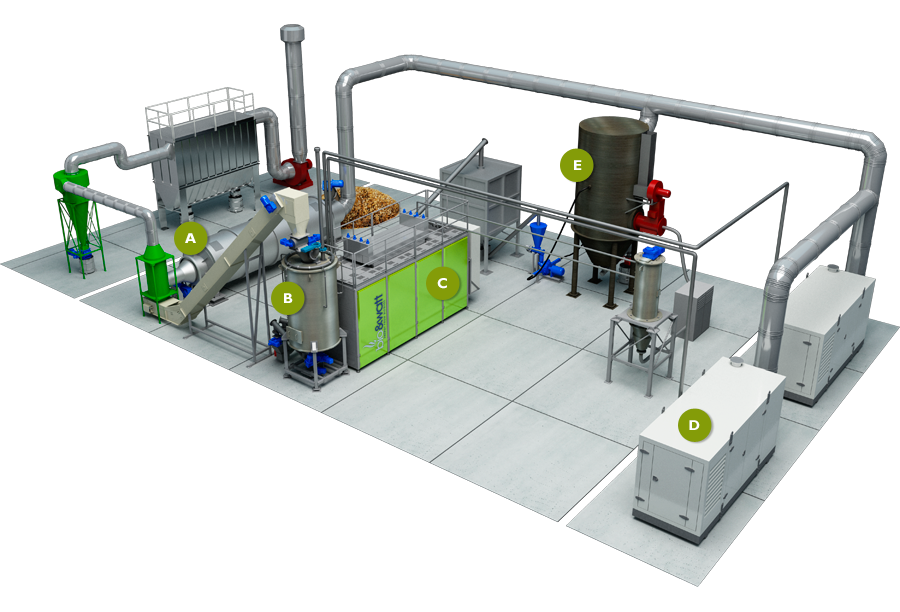

A. DRYER

| - |

Drying is required when the humidity content of the available biomass is higher than 10%

|

| - |

Dryer: temperature controlled device where the biomass humidity decreases due to evaporation, until it reaches the value required by the next phase of gasification process

|

| - |

Biomass is dried using the heat cogenerated by the plant

|

| - |

The choice of the drying technology is made on the basis of environmental conditions and customer needs (amongst the applicable: rotary drum dryers, belt/conveyor dryers, bed/grate etc.)

|

B.

GASIFIER

| - |

Gasification reactor: inside the reactor the biomass is converted into a combustible gas (syngas, from synthesis gas) through a succession of thermo-chemical reactions which take place at high temperature, without combustion, with a controlled amount of oxygen |

| - |

The carbonaceous solid co-product (char) is extracted from the bottom of the reactor and continuously fed to the oxidizer |

| - |

The syngas is directed to the next phase of gas conditioning

|

C. SYNGAS CONDITIONING

| - |

The syngas leaves the reactor at elevated temperature with a certain heating value and pollutant load, and must be conditioned (cooled and cleaned) prior to being fed to the engine. The main components of the conditioning chain are:

Cyclone separator: hot syngas leaving the reactor is first de-dusted by removing particulate through vortex separation

Wet scrubber: syngas is then sprayed with water for further cleaning and cooling (cooling increases the energy density of the gas)

Electrostatic precipitator: condensable and solid particles that may have passed the first two cleaning systems are finally removed from the flowing syngas using the force of an induced electrostatic charge. An extremely clean syngas is now ready to feed the engine |

| - |

The liquid fuel which may be produced by condensed vapors (tar or pyrolytic oil) is directly fed to the oxidizer |

D. CHP MODULE

| - |

Internal combustion engine fueled with syngas generated from biomass

|

| - |

Cogeneration: electrical power is produced by an alternator linked to the engine and sent to the grid; heat from engine’s cooling circuits and exhaust gases is recovered for thermal needs

|

E. OXIDIZER

| - |

Oxidizer: a secondary reactor specifically designed in which the liquid and solid components generated simultaneously to the gas inside the gasification reactor are converted to clean flue gas. The recovered heat is conveyed for thermal needs or converted to power through an ORC system

|

|